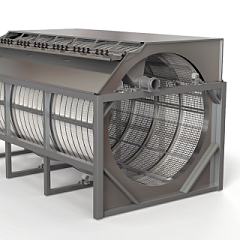

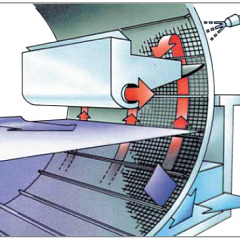

Drum filters

The drum filter is used to filter water or other liquids, in closed circuits, on fish farms, in utilities, oil refineries, food production, for wine material separation into fractions, etc. Drum filters differ in several parameters, including the key ones: flow rate and type (open/closed).