The drum filter is used for mechanical filtration of water, for example, in aquaculture (fish farming) systems with closed water supply systems. The drum filter is one of its most important elements. Filters are also used to purify water or other media in community facilities, oil refineries, food production, etc. but these industries are much smaller than the aquaculture equipment industry, in particular RAS (recirculation aquaculture systems).

Drum filters are classified according to the following main parameters:

- by design

Drum strainer designed for mechanical water purification from impurities (the most common size of impurities is 60 microns). The filter is equipped with a backwash.

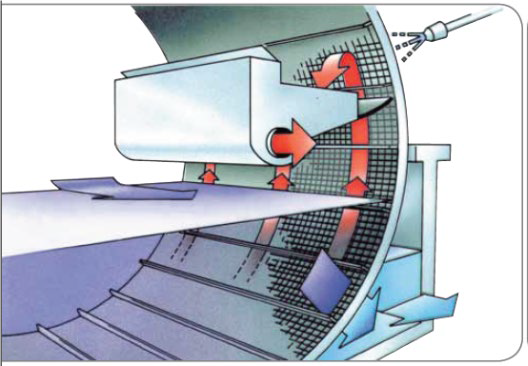

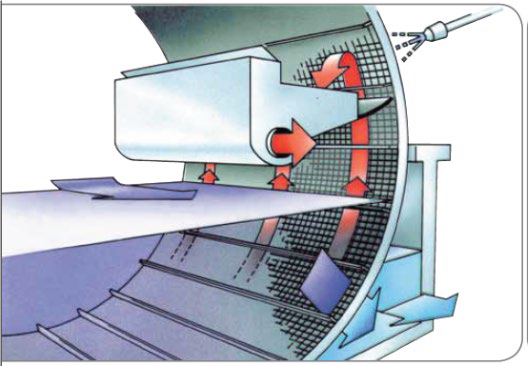

The principle of operation of the drum mesh filter:

Solid fractions of impurities are retained when water flows through a fine mesh sieve (eg 60 microns). Sludge collecting on the inner surface of the filter mesh (consisting of fish droppings released by fish) clogs the filter mesh, while the water level in the filter housing rises, after a certain time the level reaches the upper sensor, making contact. This sensor activates the backwash process, which consists in rotating the drum and flushing the filter mesh through the nozzle assembly. The water flowing from the grid with an admixture of sludge enters the wastewater disposal system.

Schematically it looks like this:

In the diagram, the red arrow shows the path of the sludge - under the action of the pump, it enters the chute, from where it flows into the sewer pipeline.

It is important to note that the drum does not rotate constantly, and the process of backwashing the filter element (mesh) starts at certain predetermined time intervals, or when the upper predetermined level is reached.

Filters can be classified by design as follows:

According to the type (method) of installation (mounting), drum mesh filters are divided into case and channel filters. At the same time, the drum itself with the filter element (mesh) does not differ structurally.

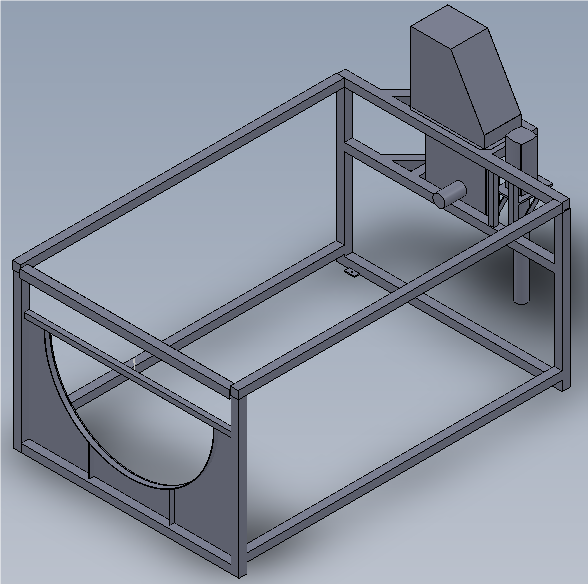

The open-channel type is a drum mounted on a frame. This is the simplest type of filter. Instead of a housing, such a filter has only a solid front end wall, dividing the entire space into "before" and "after" filtration, an open-channel drum filter is installed in a concrete open channel, the width of which is 10-20 mm larger than the width of the filter frame. At the same time, water entering through the channel flows directly into the drum, is filtered out of the drum, falling behind the solid end wall into the "after" filtration zone, then flows through the channel purified from mechanical impurities larger than 60 microns. It looks like this:

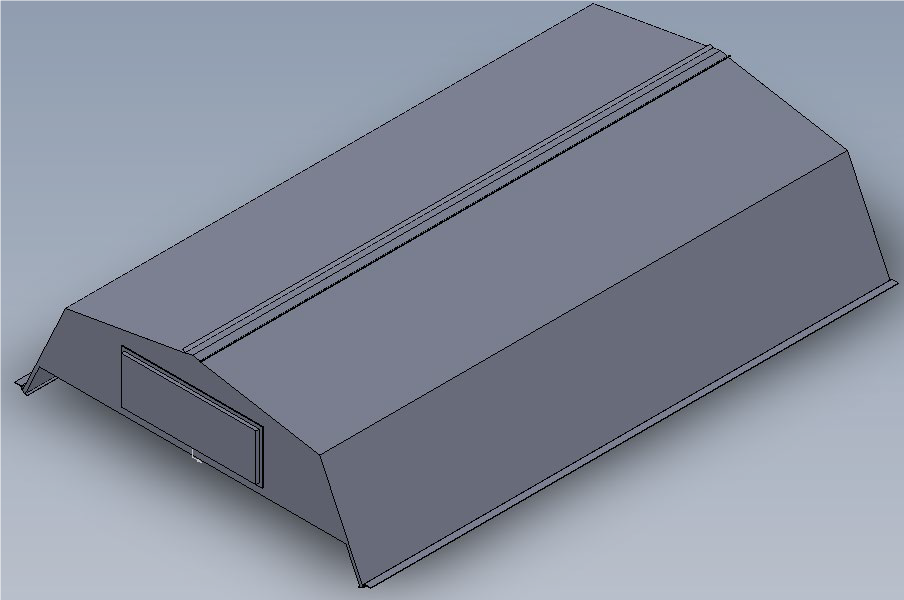

The drive is fixed on the frame, the drum is closed on top with a cover that prevents water splashing from backwashing and protects the drum from mechanical damage and prevents foreign objects from getting inside the drum, because the filter mesh can be damaged quite easily. The structural view of the frame and cover is as follows:

The frame is made of a stainless steel shaped tube, which ensures the retaining of the load of the drum with water. The lid can be made of either stainless steel or aluminum sheet or of polymeric materials such as polypropylene. Basic requirements: lightness, corrosion resistance and strength.

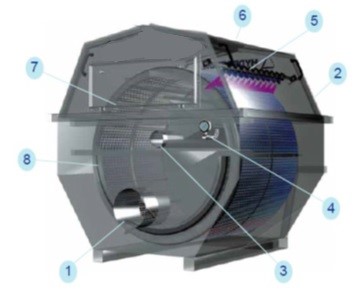

The cased type drum strainer is of the same design, but in a sealed housing. This type is intended for installation in a ready-made room, where it is unacceptable to spill water on the floor and water is supplied not through a channel, but through a pipe. It looks like this:

1 - inlet pipe

2 – water outlet tube (not visible)

3 - backwash sludge drain pipe

4 - pressure gauge at the inlet to the nozzle unit

5 - nozzle unit

6 - drum drive (not visible)

7 - filter mesh

8 - drum seal

This type of drum filter is structurally more complicated, since it requires a drum seal so that dirt does not flow from the inside to the outside of the drum. The outlet pipe is located at the bottom of the rear wall. The exact location of the pipes is determined by the water level in the filter.

If you decide to buy a drum filter for RAS, you must definitely decide on the main criteria for selecting a filter: water temperature, the amount of pollution contained in the water, and the required volume of filtering water. The sale and order of a drum mesh filter for RAS is usually carried out at the design stage of the RAS, or at operating enterprises, where these parameters are well known.

The price of a drum filter depends, first of all, on the performance and the version (cased type or open channel).

The Russian manufacturer - Livam offers to buy a drum filter at the manufacturer's price. Livam drum filters have proven themselves well due to the use of 100% stainless steel in the construction, including small fittings (bolts, studs, nuts). Equipment produced by Livam is not inferior to foreign counterparts in terms of functionality and technical characteristics.