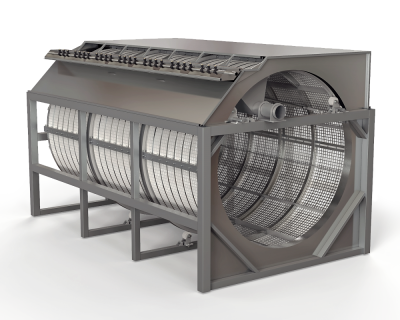

ASSIGNMENT OF THE BFL DRUM FILTER:

The mechanical drum filter is a self-cleaning filter of various capacities with a wide range of adjustments for clarification of fluids. The use of drum filters is an effective and reliable technology for separating mechanical particles from liquids. The size of the separated particles in the filtration process is in the range of 40 - 100 microns (i.e. 0.04 - 0.1 millimeters).

ADVANTAGES OF BFL DRUM FILTERS:

- Effective filtration, it’s up to 75% for solid impurities;

- High efficiency and reduced wash water consumption;

- Continuous operation,

- Automatic filter flushing without stopping the filtration process;

- Possibility of visual control of flushing;

- Reliable, leakproof 100% stainless steel construction;

- Full automation of technological processes that does not require an operator;

- Convenient operation and technical service.

APPLICATION OF BFL DRUM FILTERS:

BFL Drum filters are used where:

A high degree of purification in large volumes of water is required

Consistent filtrate quality is required

Interruption of the filtration process is undesirable

Requires high performance with small dimensions

A reliable, simple, easy-to-maintain filter unit is required

Areas of application for drum filters:

- Pre-filtration of water from surface sources before sand filters

- Additional treatment of industrial, rainfall and municipal wastewater

- In aquaculture, on fish farms, in recirculating water systems in a continuous recirculation mode

- Filtration of water in cooling systems in industrial heat exchange circuits used by cooling towers

- Filtration of water in recycling water supply systems

- Additional treatment of industrial effluents

- Purification of wash water at filtering stations, in order to return the treated wash water to the head of the structures.

Due to the fact that the drum filter uses the principle of a barrier, its filter meshes allow to retain and remove suspended particles larger than 40 microns from the water in a non-pressure mode.

The use of drum filters in industrial plants has its own characteristics:

- with an excessively large amount of contamination in the form of suspended solids (more than 200 mgl / l), the cascade principle is used, i.e. filters are sequentially installed with different filter meshes (from larger to smaller ones);

- when using drum filters for purifying petroleum products, it should be understood that filtration is possible, however, the service life of the filter mesh will be reduced and will depend on the aggressiveness of the medium.

ORDER OF BFL DRUM FILTERS:

Drum filters are selected for a specific object, taking into account the volume and temperature of water, effluents to be filtered, the amount of suspended solids in the water, requirements for filtration efficiency, and landing dimensions.

BFL drum filters are available in several standard sizes and differ in the area of the filter mesh. In each standard size, the size of the filter mesh varies depending on the characteristics of the source water and the requirements for the treatment quality.

When selecting a drum filter, one of the important conditions that must be taken into account is the frequency of automatic switching on and off of the mesh washing mode. The filtration time between washes should be several times longer than the washing time, because the main advantage of this type of equipment is the low consumption of flushing water in relation to the volume of treated wastewater. Therefore, the smaller the pore size of the filter mesh, the larger the filtration area should be and the lower the filtration rate and the lower the productivity.

It is advisable to select the filter material at a specific facility, testing various filter fabrics (nets) in order to choose the optimal one in terms of both filtration and operating costs.

The performance of a drum filter depends on the area and characteristics of the filter meshes (nominal mesh size in microns), the filtration rate through the nets and the filtration area.

For the optimal selection of the BFL drum filter, it is necessary to present the characteristics of the facility. After specifying the model of the BFL drum filter, you will be provided with the installation diagrams, dimensional drawings and technical characteristics of the drum filter required for inclusion in the project.