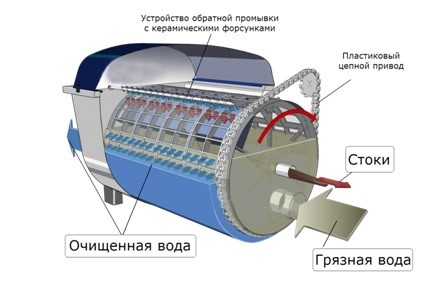

The drum filter is used to filter water or other liquids, in RAS (recirculating water systems), in community facilities for wastewater treatment, in oil refineries, in food production, for separating wine material into fractions, etc. Drum filters are divided according to several parameters, the main ones are: performance and form factor (open / closed type).

The principle of operation of a drum filter: liquid entering the filter drum passes through the filter mesh, while suspended particles settle on the filter mesh. Due to the rotation of the drum, the contamination is washed off by the washing nozzles into the receiving tray. The rotation of the drum and the start of the rinsing are controlled by the control unit. The speed is adjusted according to the characteristics of the fluid and its contamination.

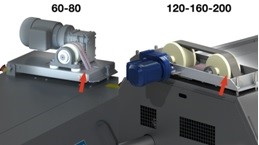

The rotation of the drum is provided by a geared motor. The drum drive is made in several designs.

- Direct drive drum filter

The direct drive is used on filters with a low capacity up to 100 m3, does not require the installation of additional parts (gears, belts, chains, etc.). This type of drive is easy to install and operate. The disadvantage of the direct drive is low power due to the lack of transmission, insufficient moisture protection due to the low location of the geared motor, as well as the need for accurate positioning and the complete absence of shaft runout, otherwise the geared motor quickly fails.

- Belt drive drum filter

A belt drive is used on filters with any capacity from 50 to 1000 m3 / h. This type of drive includes a drive and driven pulley, as well as a drive belt. This type of drive makes it possible to significantly improve the moisture protection of the gear motor, and also, due to the flexibility of the belt, dampens all the beats and vibrations of the central shaft, ensures smooth and silent operation of the drive. The disadvantage of a belt drive is the need to regularly replace the drive belt, as well as a low transmitted torque due to the possibility of belt slipping when working in a water environment.

A belt drive is used on filters with any capacity from 50 to 1000 m3 / h. This type of drive includes a drive and driven pulley, as well as a drive belt. This type of drive makes it possible to significantly improve the moisture protection of the gear motor, and also, due to the flexibility of the belt, dampens all the beats and vibrations of the central shaft, ensures smooth and silent operation of the drive. The disadvantage of a belt drive is the need to regularly replace the drive belt, as well as a low transmitted torque due to the possibility of belt slipping when working in a water environment.

- Chain drive drum filter

The chain drive is used on drum filters with a high performance, over 500 m3 / h, with a chain drive, the drive includes a drive and driven sprocket, as well as a drive chain. This type of drive can withstand heavy loads, it allows you to transmit a significant torque even in a water environment, in addition, as a belt drive, it can significantly improve the moisture resistance of the geared motor and compensate for all beats and vibrations of the central shaft. The disadvantage of a chain drive is its cost. All parts, including the chain, are difficult to manufacture, must be made of stainless steel or composite materials, which significantly affects their cost and the total cost of the drum filter. Also, the chain drive requires regular maintenance and monitoring of the chain condition.

The chain drive is used on drum filters with a high performance, over 500 m3 / h, with a chain drive, the drive includes a drive and driven sprocket, as well as a drive chain. This type of drive can withstand heavy loads, it allows you to transmit a significant torque even in a water environment, in addition, as a belt drive, it can significantly improve the moisture resistance of the geared motor and compensate for all beats and vibrations of the central shaft. The disadvantage of a chain drive is its cost. All parts, including the chain, are difficult to manufacture, must be made of stainless steel or composite materials, which significantly affects their cost and the total cost of the drum filter. Also, the chain drive requires regular maintenance and monitoring of the chain condition.

- Gear drive drum filter

The gear drive is one of the most reliable and durable drives, it is used on drum filters with any capacity from 50 to 1000 m3 / h. The drive includes a pinion gear and a gear rim. This type of drive can withstand heavy loads, and can transmit a significant torque in any environment, including oil products. It doesn't require regular maintenance. The disadvantage of the gear drive consists in the susceptibility to the gear runout and axial displacement. In addition, in the case of a gear train made of plastic, the durability of this drive leaves much to be desired. There is a risk of breaking teeth and premature wear of the gear.

The gear drive is one of the most reliable and durable drives, it is used on drum filters with any capacity from 50 to 1000 m3 / h. The drive includes a pinion gear and a gear rim. This type of drive can withstand heavy loads, and can transmit a significant torque in any environment, including oil products. It doesn't require regular maintenance. The disadvantage of the gear drive consists in the susceptibility to the gear runout and axial displacement. In addition, in the case of a gear train made of plastic, the durability of this drive leaves much to be desired. There is a risk of breaking teeth and premature wear of the gear.

When choosing a drum filter for RAS, you should definitely pay attention to the type of drum drive. Today you can find drum filters with any type of drive on sale.

The Russian manufacturer Livam offers for sale a drum filter at the manufacturer's price. Livam drum filters have given a good account of themselves owing to the use of 100% stainless steel in the construction, including small fittings (bolts, studs, nuts). To this date, life tests of various types of drum drives are underway in order to find the optimal solution in terms of price-quality ratio.

Equipment produced by Livam is not inferior to foreign counterparts in terms of functionality and technical characteristics.